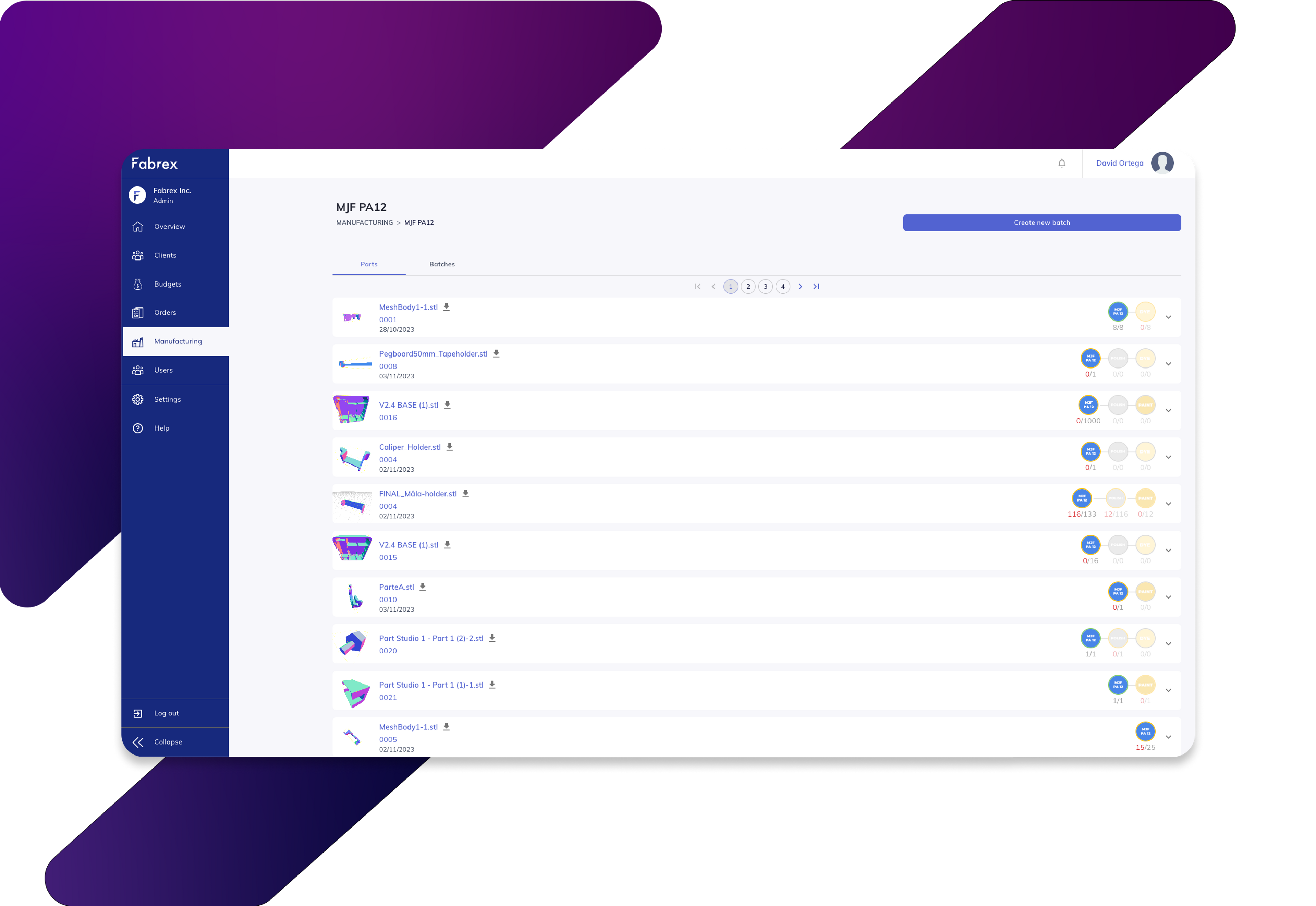

Manufacturing

Unlock unparalleled efficiency in your manufacturing processes with Fabrex's robust Management system.

Production Management

Plan, orchestrate, and execute every order

Masterful Planning

Fabrex provides a comprehensive planning toolkit that anticipates your needs, balances workloads, and optimizes resource allocation.

Orchestrate with Ease

From the procurement of materials to the assignment of workstations, Fabrex streamlines the orchestration of complex manufacturing task.

On-Time Delivery

Track the progress of each order, predict potential delays, and implement contingency plans to ensure on-time delivery, every time.

Quality at Every Step

Monitor quality control checkpoints, gather feedback, and enforce the highest standards to ensure that every product meets your clients' expectations

Intelligent Automation

Fabrex integrates with your existing systems to automate routine tasks, reduce manual intervention, and free up your workforce to focus on what they do best.

Data-Driven Decisions

Armed with real-time data and analytics, make informed decisions that drive business growth.

Collaborative Ecosystem

Sales, manufacturing, and logistics teams can communicate effortlessly, ensuring that every handoff is seamless and no detail is overlooked.

Part Traceability

Elevate your manufacturing process with the comprehensive part traceability system

End-to-End Visibility

Navigate the complexities of client budget management effortlessly. Fabrex grants you a bird's-eye view of every client's budget.

Precision in Every Process

Gain insights into the life cycle of each part. Whether it’s a single screw or a complex assembly, Fabrex captures and stores all relevant data

Quality Control

When an issue arises, quickly identify and resolve it by tracing back through every stage of the manufacturing process.

Compliance Made Simple

Fabrex makes it simple to prove compliance with various quality management systems, providing peace of mind and saving time during audits.

Risk Reduction

With comprehensive part traceability, pinpointing a problem down to a specific batch, machine, or operator allows for swift corrective actions.

Operational Excellence

Fabrex's traceability feature not only monitors the progress of parts but also provides analytics that help you optimize your operations.

Seamless Integration

Integrate the part traceability system with other features such as Production Management and Quality Assurance for a unified approach.

Quality Assurance

Ensure excellence in every product with Fabrex’s Quality Assurance (QA) feature

Batch-Level Inspection

Every batch of products undergoes a rigorous QA process upon completion of each manufacturing stage.

Automated QA Triggers

This built-in trigger mechanism ensures no batch moves to the next stage without passing through your defined quality checkpoints.

Real-Time Quality Feedback

Real-time feedback enables quick action, whether that means sending parts back for rework or repeating the process.

Streamlined Rework Process

Fabrex simplifies the management of rework, tracking parts as they are sent back through production processes for correction.

Quality Trends Analysis

With Fabrex, continuous improvement becomes data-driven, allowing you to refine processes, enhance training, or make adjustments to equipment to improve overall quality.

Integrative Quality Management

Fabrex’s QA feature integrates seamlessly with production management and part traceability systems, ensuring that quality assurance is a cohesive part.

Compliance Documentation

This detailed record-keeping is invaluable during audits and for clients who demand transparency and assurance of quality.

Discover other solutions to empower your business: